Description

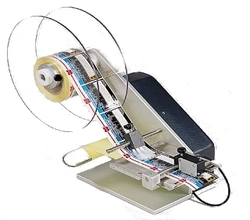

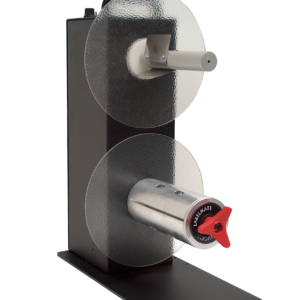

| Speed | 5 to 15 m/min |

|---|---|

| Max. label width | 100/140 mm |

| Min. label width | 10 mm |

| Max. label length | 500 mm (other sizes on request) |

| Max. container diameter | 100 mm |

| Min. container diameter | 20 mm |

| Engine type | Step/step |

| Stop label reader | Fork photocell or microswitch only for transparent labels |

| Max. label spool diameter | 300 mm |

| Label spool core diameter | Between 38 mm and 76 mm |

| Tolerance for applying labels at top speed | 0.3 mm |

| Microprocessor-controlled electronic digital control unit and display | It allows perfect adjustment of label progression, without resorting to mechanical movements of the photocell |

| Adjustments available | – Speed dispensing, – Application delay, – Label air blow Xme adjustment, – Label suction time |

| Motor block | Aluminum crankcase with 4 adjustable feet |

| Weight | Approx. 20 kg |

| Max. overall dimensions | 850 mm x 500 mm x 210 mm |

| Power supply | 220 or 110 V 50/60 Hz |

| Operating temperature | Between +40°C and 0°C |

| Optional | – Self-dimensioning sensor for automatic reading of product size, – Sensor for detecting label on buffer, – Supplementary buffer, – Supplementary positioning jig, – Hot/dry print group, – Special photocell for transparent labels |